You know you have an amazing family when...

10/09/17 10:16 Filed in: Ideas

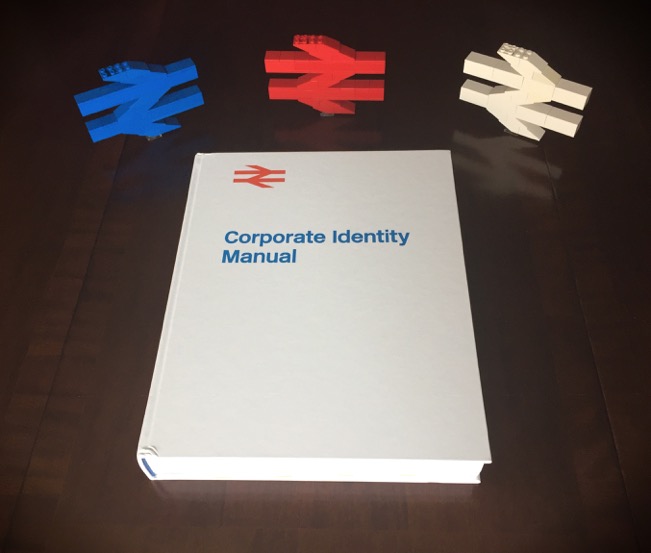

A couple of weeks ago, I finally received my birthday present in the post from my wife: a gorgeous reprint of the British Rail Corporate Identity Manual.

On my birthday itself, my eldest son presented me with brick-built BR double arrow logos! I can't believe that I hadn't thought of making them myself. In any case, I doubt I could do better than his brilliant builds. I think he perfectly captured their size and proportion in an elegant and clean stud-ups design.

The BR identity manual is a feast for the eyes, especially for train and graphic design geeks such as myself. Its lovely to see many similar identity manuals of this era being re-issued through the magic of crowd funding projects. Examples include the NYC subway, the EPA, IBM, and other public and private sector agency identity manuals being lovingly reproduced for posterity. Its a pity that the same care and attention to quality public branding and imagery is not often found these days. Not every logo or brand needs to become a design icon; however, it would be nice to simply avoid the garish self-indulgence of the latest trendy design fads (I'm looking at you Xerox and others who embraced trendy 3D-swooshy logos!)

I couldn't have asked for better presents as these. Sometimes love can be expressed in the purity of a logo! (and not necessarily a heart-shaped one!)

Kit 7764 JIA Polybulk Hopper Wagon Available

17/04/17 15:49 Filed in: News

At long last, I have found time to complete the instructions for the British Rail Polybulk covered hopper (TOPS code JIA). This wagon design is quite robust and looks quite impressive in its striking green livery—a livery made possible with availability of 2x4 tiles and 2x4 curved slopes in green. I have road tested this wagon extensively during shows and it works very well.

At 535 pieces, it is quite efficient with parts for a wagon of its size. If you can build multiple copies, this wagon looks impressive in a rake of several vehicles.

Available now at the kit store.

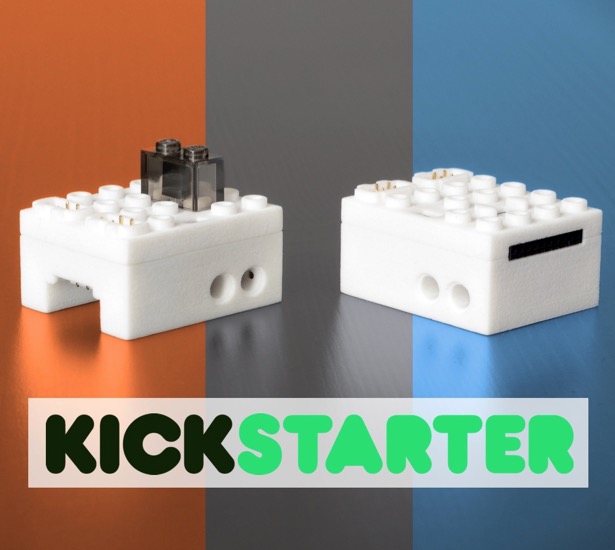

Support the PFx Brick!

27/03/17 09:22 Filed in: News

After many months of hard work, Jason Allemann and I are launching our Kickstarter campaign to hopefully bring the PFx Brick in to mass production. The PFx Brick has truly been a labour of love and we're super excited about its potential. The mix of emotions before launching a campaign like this is quite unusual. It is a combination of excitement, trepidation, vulnerability, and impatience. Exposing the fruits of one's labour to the collective judgement of the world in a focused 30 day period is quite a unique experience. It will be very interesting to see how this 30 day campaign unfolds!

Campaign start: Mon Mar 27, 2017 10:00am EDT

Campaign ends: Tue Apr 25, 2017

Heavy Metal

17/01/17 22:24 Filed in: Information

I'm not normally a fan of the "un-boxing" photo or video genre; however, I'll make an exception in this case!

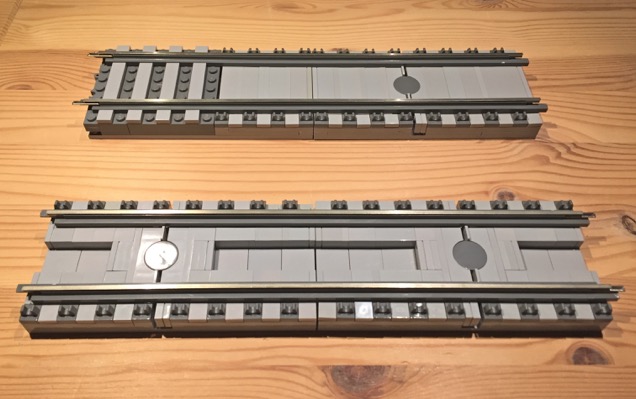

After quite a long wait, I have finally received my much anticipated delivery of ME Models metal track elements.

It appears that the wait has been worth it. Initial exploration with assembling some track sections has put to rest any anxieties of adopting a novel, yet unconventional method of metalizing plastic track. Some observations:

1) The clutch power is much improved over previous ME track. The tendency for ballasted track sections to "explode" with any subtle twisting forces, resulted in me solvent welding the rails to the ballast plates.

2) Rail joints are smooth and seamless. This is not a surprise given that these are effectively HO/OO rail sections with fishplates. This will lead to very smooth running characteristics and superb electrical performance.

3) Nickel silver rail will resist corrosion and improve electrical performance.

4) Separate rail sections will broaden the opportunity to "scratch build" a wider variety of track. I've posted some track sections built to represent precast concrete rail-beds common with many high speed railway lines.

5) Flange way clearance is better without flanges running on the rail base.

My only criticism is the possibility of creating uneven rail height during assembly. My initial tendency when assembling a rail section was to apply force on top of the rail head to secure it to the tie-plates. This would sometimes result in pushing the metal rail insert further into its groove resulting in uneven rail height. I now have to be conscious to apply force to the rail base flange rather than the rail head.

Overall, I say its a big win for us Lego train fans. The only remaining piece of the puzzle is motors with metal wheels!

Happy Holidays from Fx Bricks

21/12/16 12:48 Filed in: News

Fx who?

I guess I should come clean. A lot of the reason I haven't posted for while this year is because I've been working on this. No, not a winter village scene which can built from sets in 2 hours! :) I have been working on the electronics which power this scene as shown in this video...

These models are powered by the PFx Brick. A new product developed in collaboration with my good friend Jason Allemann (yes, the same Jason who designed the Lego Ideas marble maze). We've started a company called Fx Bricks, and we're hoping to bring the PFx Brick into production with the help of a crowd-funding campaign in the near future. We hope the PFx Brick will just be a starting point for many cool products aimed at integrating electronics with bricks.

I won't bore you with the details, you can visit fxbricks.com for that. Suffice to say, what started as an effort to bring the awesome technology of the model train world (i.e. DCC sound decoders) to Lego trains, became a more useful and general purpose product. A product which can bring the magic of lighting, sound and animation to models of any theme, shape, or size!

Merry Christmas to all my Lego friends, and all the best for 2017!

I guess I should come clean. A lot of the reason I haven't posted for while this year is because I've been working on this. No, not a winter village scene which can built from sets in 2 hours! :) I have been working on the electronics which power this scene as shown in this video...

These models are powered by the PFx Brick. A new product developed in collaboration with my good friend Jason Allemann (yes, the same Jason who designed the Lego Ideas marble maze). We've started a company called Fx Bricks, and we're hoping to bring the PFx Brick into production with the help of a crowd-funding campaign in the near future. We hope the PFx Brick will just be a starting point for many cool products aimed at integrating electronics with bricks.

I won't bore you with the details, you can visit fxbricks.com for that. Suffice to say, what started as an effort to bring the awesome technology of the model train world (i.e. DCC sound decoders) to Lego trains, became a more useful and general purpose product. A product which can bring the magic of lighting, sound and animation to models of any theme, shape, or size!

Merry Christmas to all my Lego friends, and all the best for 2017!